What You Need In Anti-counterfeit Packaging Today And Why

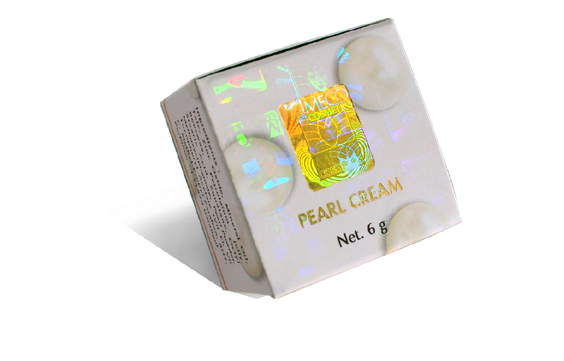

Examples of available anti-counterfeiting features on packaging include emerging objects under different light (left), and holograms and micro-holograms (right).

Companies now organize more anti-counterfeit programs and spend more money on them than ever before. More than half of top managers say that fighting fakes is a critical priority, according to recent research of MarkMonitor, and they are ready to invest even more than now. It makes sense because counterfeiters are not small shops anymore but rather operators of huge manufacturing capacities, sometimes even bigger than original brand producers.

However, the counterfeiters adapt themselves to the new situation fast. Statistics of European Custome Office show declining number of captured fakes but growth in overall value. Attackers concentrate on more expensive products and learn more sophisticated technologies. According to preliminary data of Intl. Trademark Assn., the total cost of fakes exceeded $500 billion last year.

The anti-counterfeiting landscape is changing, and packaging producers should acknowledge it. Here is a summary of critical general guidelines.

There are three basic strategies for protection. They are not mutually exclusive, are often implemented together and have limitations:

1. Use law protection and enforcement to prevent counterfeiters from getting to the markets. To this group of provisions, attempts to move costs to the third parties, such as the market operators, can also be counted. Amazon, Alibaba and other big ecommerce companies now face lawsuits for failing to do enough to protect their markets against fakes.

Limitation: Such provision can lead to the destruction of some markets.

Some products have already been delisted from Amazon. After all, some consultants recommend to limit the number of sales points and dealers or implement exclusive dealership. Anti-counterfeit protection is thus paid by a loss of opportunities.

Moreover, law enforcement needs a kind of proof—so provisions from the next two strategies need to be implemented.

2. Tracking and tracing each individual product from production through distributors and stores...up to second hand shops.

Limitation: Personal data protection and sometimes also business data protection.

Moreover, a physical protective element needs to be added anyway. Otherwise, it may happen that a user reads a QR [quick response] code and gets information about the history of the product but still cannot be sure that the product has not be replaced.

3. Adding protective elements so that a customer can differentiate between genuine and fake on his/her own.

Limitations: Some customers buy fakes intentionally.

Academic researchers show that this may be the case for a significant proportion of the market. Here we face the more general problem. If clients want fakes, it is close to impossible to stop them. The manufacturer should ask a question: Why the client doesn‘t see sufficient benefits in genuine products.

Demand for packaging with anti-counterfeit features will grow. Packaging suppliers will be asked for a recommendation of most suitable elements. Selection of elements must be based on knowledge of inspecting persons. It is critical that the protection fits their abilities.

Anti-counterfeiting solution criteria

With this reservation, the following features of protective elements are necessary:

• Discriminability. Even an inspecting person with minimal training should be able to identify genuineness. Let us show the difference on the recent generation of holograms, the most reliable protection technology available. The hologram may include a visual illusion based on swapping between logo and digits or swapping between grey and black color. Such protection would not be powerful because most inspecting persons cannot differentiate it from other holograms that include the same logo. On the other hand, it is possible to implement amusing effects such as dancing bear or 3D flower with changing colors into the hologram. They would create substantially strong protection.

• Self Destructiveness. The protection element must guarantee that any attempt of its removal and placing on another package will result in its irreversible destruction. Drawing with special inks is an excellent tool for ensuring self destructiveness. If a hologram is applied, it should consist of smaller parts and come apart during handling attempts.

• Inimitability. It is critical that counterfeiters are not able to create something similar. Meeting this requirement is difficult for simple technologies such as watermarks, drawing with special inks or old generations holograms.

On the other end of the scale, you can find advanced holograms with extremely high resolution (using electron beam instead laser) and special mathematic algorithms. They are applied to ID cards, and the best of them deter counterfeiters even from attempts to imitate.

Some manufacturers tend to place as many protection elements as possible on the packaging. However, behavioral studies show that too many elements result in confusion with inspectors rather than in security enhancement. We recommend up to three large visible elements.

Hidden elements can also be added to enable the inspecting person to go deeper in case of suspicion. This additional (hidden) level of protection can be based on different measures:

1. Further visual effects in the hologram, such as emerging objects under red light coming from a defined angle.

2. Microletters or other microscopic symbols or spots.

3. Protected substance. Paper or plastic for package making can include microscopic markers. Markers of different security level can be used.

For example, protective fibers add some protection. However, they can be removed and abused easily. Plastic microparticles with manufacturer or product information are stronger because counterfeiters cannot transfer them between different products and series. However, they can still be imitated. And with micro-holograms, there is a full hologram with all visual effects on each particle. Imitation of micro-holograms is impossible or close to impossible.

Micromarkers establish a de facto entire market on their own. A discussion of micromarkers needs more space than can be dedicated to this article.

In any case, when deciding on anti-counterfeit packaging, it is also necessary to consider:

• A balance between protection element costs and product price. The designer should understand not just his/her costs but also cost for counterfeiters.

• The lifecycle of the product, including packaging lifecycle (time and conditions). It’s a problem if the product or packaging lasts longer than the protection feature—for example, if a label is put directly on a long-living product. Some protection elements, such as special printing inks or even some holograms, lose their quality in two to three years or sooner. On the other hand, it is not good if the anti-counterfeiting element endures much longer than the rest of packaging because of the risk of abuse and/or of copying. Anti-counterfeit solution design should be based on this knowledge. Packaging producers who manage it can become strategic partners of big brands.