OFFSET PRINTING

A printing technique which uses printing plates where printing and spacing elements lie in one plane. Inks are transferred to the print-receiving surface not directly from the printing plate but via the offset cylinder covered with a rubber blanket.

Traditional offset is a printing technique that includes moistening. Moistening enables the separation of printing and spacing elements due to the difference in their physicochemical properties. The spacing elements attract water while the printing elements attract ink. Every time before ink is applied, the printing plate is dampened with water which adheres to the spacing elements. So they do not attract ink afterwards.

Characteristic features of traditional offset printing:

the substrate is not deformed;

ink in the strokes is evenly distributed, the thickness of the ink layer is constant;

paper fibers can be seen under the strokes.

Dry offset is a printing technique that does not include moistening. In this case, silicone is used to create a layer of spacing elements on the printing plate.

Letterset (indirect letterpress printing) is a technique which combines the elements of letterpress and offset printing. An image is transferred from the letterpress printing plate to the intermediate offset cylinder and then to the print-receiving material.

Letterset prints are characterized by an obviously thicker layer of ink along the boundaries of the print which is typical for letterpress printing (but not for traditional offset printing).

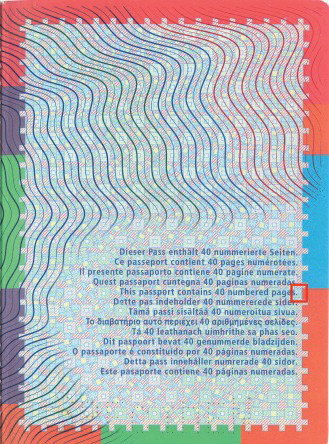

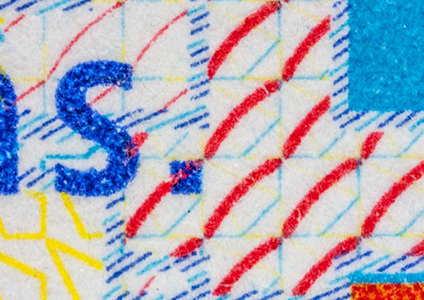

a b

a — Paper substrate;

b — Background design pattern. Zoomed fragment. Offset printing. No relief. Even ink distribution. Paper texture is seen under the strokes

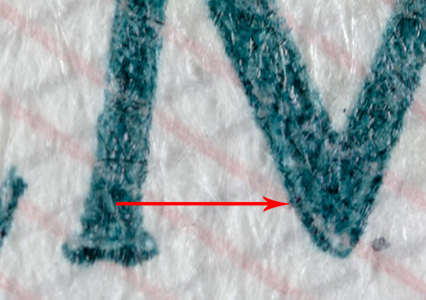

a b

a — Paper substrate;

b — Text. Zoomed fragment. Letterset. A thick layer of ink along the boundaries of the print (marked with an arrow)