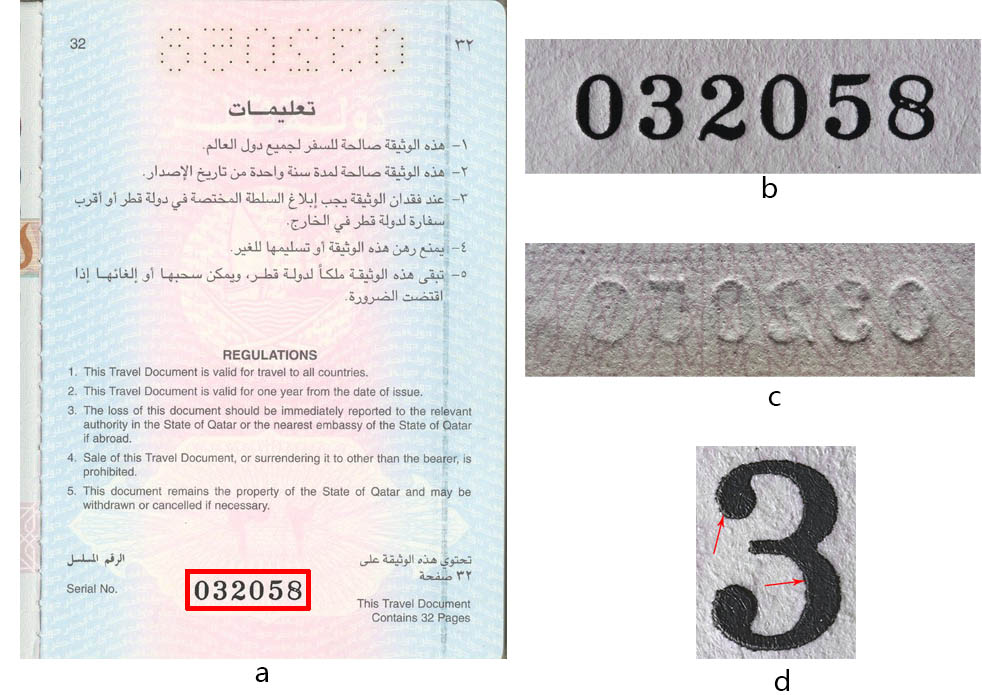

LETTERPRESS PRINTING

A printing technique when ink is applied to a substrate from a printing plate with printing elements raised above spacing elements. During printing spacing elements do not touch the print-receiving material. The process is carried out under high pressure (at least 15 kg/cm

A printing technique when ink is applied to a substrate from a printing plate with printing elements raised above spacing elements. During printing spacing elements do not touch the print-receiving material. The process is carried out under high pressure (at least 15 kg/cm2) with the use of fast-drying inks.

Special features of the print:

uneven ink distribution in strokes: less ink in the middle than along the edges;

a rim formed by the ink along the edges of a stroke;

deformation of the print-receiving material: protuberance on the back side of a sheet and indentation on the front side of a sheet in the area where the print is applied.

Letterpress printing is often used for printing serial numbers, barcodes, and design elements of covers.

a — Paper substrate;

b — Serial number. Front side of the print. Letterpress. Uneven ink distribution in strokes. White light;

c — Substrate deformation: protuberance on the back side of a sheet caused by the pressure of the printing plate. Oblique light;

d — Zoomed fragment. A rim along the edge of the stroke (marked with arrows)

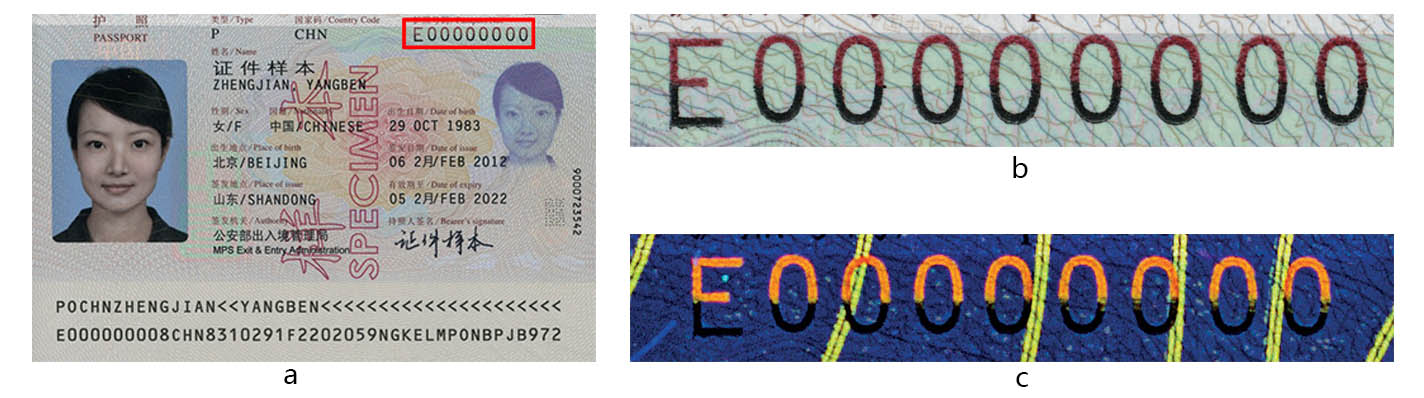

a — Paper substrate;

b — Serial number. Two inks applied while using the Orlov printing method. Letterpress. White light;

c — UV light