LENTICULAR TECHNOLOGY

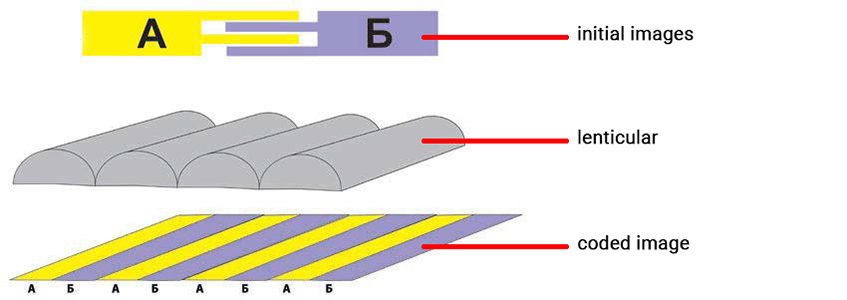

A method of printing and visualizing an image using lenticular lenses which are used to produce printed images which seem to change or move when viewed from different angles. The term Lenticular is used to define the repeating rows of convex lenses on the front surface of a plastic sheet. The reverse side of the material, however, is a flat surface. Each lens magnifies and projects micro-slices of image data printed on the reverse side. The lenticular technology means that initial images are cut into stripes which are joined so that there is a pair of stripes under each lens — one stripe from one image and the other stripe from the other image. Each lenticular operates as a magnifier which magnifies and isolates only one of the initial images. Coded images are applied by means of printing or laser engraving.

Lenticular technology scheme. Initial A and B images are coded i.e. they are cut into stripes the number of which is a multiple of the number of lenses

Image visualization when viewed at different angles. Initial images alternate when viewed at different angles

a

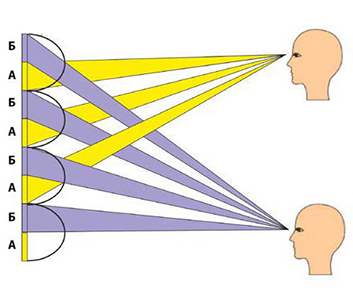

a — Polymer substrate;

b — Multiple laser image (MLI). Consists of two initial images: holder's photo and signature. Each image is clearly visible under a certain angle of observation;

c — Zoomed fragment. An array of parallel cylindrical lenses with relief surface. Felt to touch. Blind embossing

a

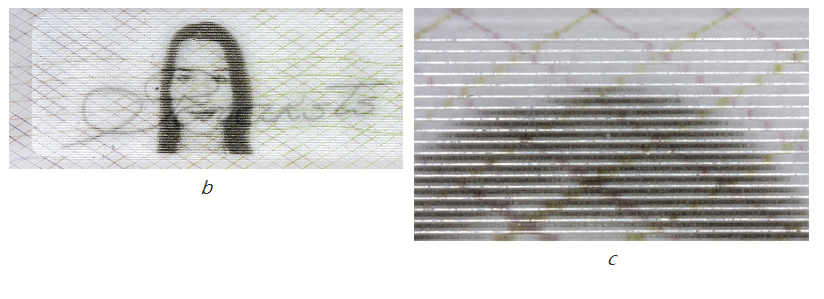

a — Polymer substrate;

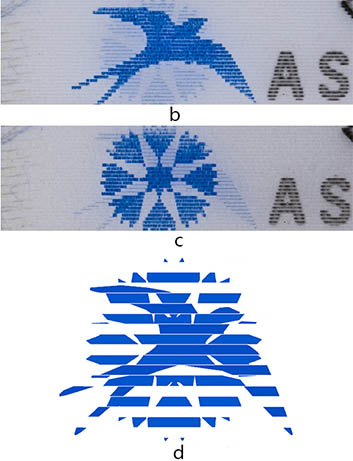

b — security feature. View at an observation angle of 45°. Image of a bird in the foreground;

c — Depending on the angle of observation, one or the other initial image is visible. View at an observation angle of 135º. Image of a flower in the foreground;

d — Scheme of forming a coded image. The initial images of the bird and the flower are cut into stripes. The stripes interchange